Qingdao Migo Glass Co.,Ltd is one of the most professional padel court tempered glass manufacturers and suppliers in China. If you want to wholesale high quality glass products made in China, you can contact us. We have a professional factory at your service, please feel free to buy customized glass products at a reasonable price from us.

Explore tempered glass for padel court

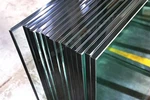

Tempered glass is widely used in sports facilities such as Padel court due to its superior strength, safety and transparency. As a modern building material, tempered glass plays an important role in enhancing the audience's experience and safety.

This article will explore the production process, quality inspection methods and packaging methods of tempered glass.

The production process of tempered glass

Tempered glass has a high hardness, so a suitable drill bit, such as a diamond drill bit or a carbide drill bit, is required to ensure a smooth drilling process.

On a fixed workbench, use an electric drill or a special glass drill to drill holes. The speed and feed rate of the drill bit should be controlled during operation to prevent overheating and cracking. Usually, water can be used as a coolant during the drilling process to reduce the temperature and reduce the risk of glass breakage.

After drilling, the edges of the holes need to be processed to remove burrs and sharp edges to ensure that the holes are smooth and avoid damage during subsequent installation.

Fix the tempered glass firmly on the edge grinder to ensure that it will not move during the grinding process.

Turn on the edge grinder, set the appropriate speed and pressure, and start grinding. Grinding time and speed should be adjusted according to the thickness and material of the glass to avoid over-grinding.

After edge grinding, the glass needs to be cleaned to remove dust and impurities generated during the grinding process. Then a visual inspection is carried out to ensure that the edge is smooth and meets the standards.

Quality inspection methods

In the production of tempered glass, quality inspection is an important part of ensuring product quality. Generally speaking, quality inspection includes the following steps:

Dimension measurement

Use professional instruments to measure the size of the glass to ensure that it meets the design specifications. The accuracy of the size directly affects the accuracy of subsequent installation.

Strength test

Tempered glass needs to undergo compression and impact tests, usually using drop hammer method and bending test method to ensure that its strength meets industry standards.

Thermal stability test

Tempered glass is tested for thermal stability to ensure that it will not break under extreme temperature changes. This usually involves exposing the glass to high and low temperature environments and observing its performance.

Packaging method

The packaging of tempered glass is crucial and directly affects safety during transportation. The correct packaging method can effectively reduce the risk of damage during transportation.

Shockproof material

When packaging, shockproof materials such as foam plastics, bubble film or special shockproof paper are usually used to wrap the glass to ensure that it can absorb vibration and impact during transportation.

Wooden frame support

During the packaging process, tempered glass is usually placed in a wooden frame or special carton to ensure its stability during transportation. The wooden frame not only provides good support but also avoids direct contact between glass and reduces the risk of breakage.

Labels and logos

Each packaging unit must be clearly labeled and labeled, including the "fragile item" logo, product specifications, production date and other information. This information helps transportation and warehousing personnel to handle and store correctly.

Stacking specifications

During transportation, tempered glass must follow stacking specifications to avoid damage caused by overweight and improper stacking. The loading of the transport vehicle should also ensure the stability of the glass to avoid displacement during driving.

The application of tempered glass in Padel court not only improves the safety and viewing experience of the venue, but its production process, quality inspection methods and packaging methods are also strictly standardized in the industry.

Hot Tags: padel court tempered glass suppliers China, manufacturers, factory, wholesale, customized, cheap, buy discount, in stock, price, made in China, Better Glass Supplier Padel Court, Classic Padel Court Supplier, Custom Padel Courts, Padel Tennis Courts, Tempered Padel Court Glass Factory, Trustworthy Glass Padel Court Manufacturer

![[[smallImgAlt]]](/uploads/10535/page/explore-tempered-glass-for-padel-court7b7d5.jpg)