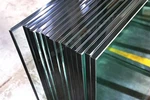

Qingdao Migo Glass Co.,Ltd is one of the most professional 6.15mm 8.15mm 10.15mm vacuum insulated window glass manufacturers and suppliers in China. If you want to wholesale high quality glass products made in China, you can contact us. We have a professional factory at your service, please feel free to buy customized glass products at a reasonable price from us.

Understanding Vacuum Insulated Glass: A Modern Solution for Building Needs

Vacuum Insulated Glass (VIG) is a revolutionary advancement in glazing technology that has garnered significant attention in the construction industry in recent years. With its exceptional thermal performance and energy efficiency, VIG is increasingly being chosen over traditional double glazing units. This article explores what vacuum insulated glass is, the specific building demands that necessitate its use, and the reasons behind its growing popularity as a preferred choice in modern architecture.

What is Vacuum Insulated Glass?

Vacuum insulated glass consists of two or more glass panes separated by a vacuum. This vacuum serves as an insulator, dramatically reducing heat transfer through conduction and convection. Unlike conventional double glazing, which typically contains air or inert gases such as argon between the panes, VIG minimizes thermal bridging and enhances insulation performance by relying solely on the vacuum.

Key Features of Vacuum Insulated Glass

High Insulation Value: One of the standout features of VIG is its impressive thermal transmittance (U-value), which can reach as low as 0.5 W/m²K. This is significantly better than standard double glazing, which usually has U-values ranging from 1.0 to 2.0 W/m²K. The lower the U-value, the better the insulation, meaning reduced energy consumption for heating and cooling.

Slim Profile: VIG units are notably thinner than traditional double glazing. This slim design allows for more flexibility in architectural design and enables the creation of slimmer window frames, giving buildings a modern aesthetic appeal.

Lightweight: The reduced weight of VIG compared to conventional glazing units facilitates easier installation and can decrease the structural load on buildings. This characteristic is particularly advantageous for retrofitting older structures.

Noise Reduction: The vacuum between the glass panes also provides excellent sound insulation, making VIG an ideal choice for buildings in noisy urban environments.

Building Demands for Vacuum Insulated Glass

As energy efficiency and sustainability become paramount in construction, several building demands align perfectly with the advantages of vacuum insulated glass:

1. Energy Efficiency Standards

With global initiatives aimed at reducing carbon footprints, building codes are becoming increasingly stringent regarding energy efficiency. VIG's outstanding insulation properties help meet or exceed these standards, making it an attractive option for builders looking to achieve energy-efficient certifications such as LEED (Leadership in Energy and Environmental Design).

2. Sustainable Design

Architects and builders are increasingly prioritizing sustainable design practices. VIG contributes to energy savings by reducing heating and cooling demands, which translates into lower energy bills and a reduced environmental impact over the life cycle of a building. This aligns well with the goals of sustainable architecture, which seeks to minimize energy use and enhance indoor environmental quality.

3. Comfort and Performance

VIG enhances indoor comfort by maintaining stable temperatures and minimizing cold drafts. This is particularly beneficial in regions with extreme weather conditions. Furthermore, the excellent acoustic insulation helps reduce noise pollution, making it an ideal choice for residential buildings located near busy roads or industrial areas.

4. Aesthetic Considerations

The slim profile of VIG allows for larger glass surfaces, providing unobstructed views and an abundance of natural light. This enhances the overall aesthetic of a building, aligning with modern architectural trends that emphasize openness and connectivity with the outdoors.

Growing Popularity of Vacuum Insulated Glass

The shift towards vacuum insulated glass can be attributed to several factors:

1. Technological Advancements

Recent advancements in manufacturing processes have made VIG more accessible and cost-effective. Improved techniques for creating and sealing the vacuum have enhanced the quality and durability of VIG units, allowing for mass production and wider availability in the market.

2. Performance Benefits

VIG significantly outperforms double glazing in terms of thermal and acoustic performance. As the demand for high-performance building materials increases, VIG's superior insulation properties make it a compelling choice for builders and architects looking to enhance the energy efficiency of their projects.

3. Regulatory Compliance

As building regulations evolve to prioritize energy efficiency and sustainability, VIG provides a straightforward solution for compliance. Builders can confidently use VIG to meet or exceed energy performance requirements, avoiding potential penalties or the need for costly retrofits.

4. Market Demand for Energy-Efficient Solutions

As consumers become more conscious of energy efficiency and sustainability, there is a growing demand for buildings that reflect these values. VIG helps meet this demand, appealing to environmentally conscious buyers and tenants who prioritize energy savings and sustainable living.

5. Cost-Effectiveness Over Time

While the initial investment in vacuum insulated glass can be higher than traditional double glazing, the long-term savings on energy costs can offset this expense. Buildings equipped with VIG often see reduced heating and cooling bills, leading to significant savings over time. This economic advantage is increasingly being recognized by property developers and homeowners alike.

Application in Various Building Types

Vacuum insulated glass is versatile and can be used in a wide range of applications, including:

Residential Buildings: Homeowners looking to improve energy efficiency and comfort are increasingly choosing VIG for new builds and renovations. Its ability to enhance thermal performance while maintaining aesthetic appeal makes it a popular choice in upscale housing markets.

Commercial Buildings: For commercial properties, energy costs can represent a significant portion of operating expenses. Utilizing VIG in office buildings, hotels, and retail spaces can lead to substantial savings, making these properties more attractive to investors.

High-Performance Buildings: In structures aiming for high-performance certifications, such as Zero Energy Buildings (ZEB) or Passive House standards, VIG is becoming an essential component. Its superior insulation properties contribute to achieving the stringent energy demands of these certifications.

Renovation Projects: Many older buildings are being retrofitted with vacuum insulated glass to enhance energy efficiency without compromising the historical integrity of the structure. This has become particularly important in urban areas where preserving architectural heritage is a priority.

Challenges and Considerations

Despite its many advantages, there are challenges to consider when using vacuum insulated glass:

Cost: The initial cost of VIG can be higher than traditional glazing options. However, the long-term energy savings often justify the investment.

Manufacturing Limitations: The production of VIG requires specialized equipment and techniques, which may not be available in all regions. This can limit availability and increase lead times for projects.

Installation Expertise: Proper installation is critical to the performance of VIG. Ensuring that contractors are trained and experienced in handling and installing VIG is essential to avoid issues related to seal integrity and insulation performance.

Market Awareness: As a relatively newer technology, there may be a lack of awareness and understanding of vacuum insulated glass among some builders, architects, and consumers. Educating stakeholders about its benefits and applications is crucial for its broader adoption.

Conclusion

Vacuum insulated glass represents a significant advancement in glazing technology, addressing modern demands for energy efficiency, sustainability, and design flexibility. Its superior thermal performance, combined with a slim profile and reduced weight, makes it an attractive alternative to traditional double glazing units.

As building codes become stricter and consumer preferences shift toward more sustainable options, the popularity of vacuum insulated glass is likely to continue rising. It not only meets the current needs of builders and architects but also aligns with broader goals of creating energy-efficient, comfortable, and sustainable living spaces for the future.

In summary, the transition to vacuum insulated glass showcases the construction industry's commitment to innovation and sustainability. By embracing new technologies like VIG, we can create buildings that are not only functional and aesthetically pleasing but also environmentally responsible. As we look ahead, VIG stands poised to play a crucial role in shaping the future of architecture and building design.

Hot Tags: 6.15mm 8.15mm 10.15mm vacuum insulated window glass suppliers China, manufacturers, factory, wholesale, customized, cheap, buy discount, in stock, price, made in China, Insulated Glass Doors, Insulated Glass Windows, Sealed Double Glazed Units, Sound Insulation Glass