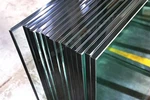

What is Ultra-clear (Low-Iron) Tempered Glass?

Ultra-clear tempered glass, also known as low-iron tempered glass, is a premium architectural safety glass produced with extremely low iron content (Fe₂O₃ ≤ 0.015%). This ultra-low iron level significantly reduces the natural greenish tint found in regular tempered glass, delivering higher visible light transmittance, crystal-clear clarity, and true color rendering.

Manufactured through advanced thermal tempering, ultra-clear tempered glass from MIGO GLASS provides 4–5 times the strength of standard annealed glass while offering exceptional optical performance-making it the preferred choice for luxury architecture, modern interiors, display cases, and high-end commercial environments.

Key Features & Advantages of Ultra-clear Tempered Glass

✔ Ultra-High Transparency

Visible light transmittance up to 91%–92%

100% color fidelity with minimal green tint

Ideal for luxury architectural and decorative applications

✔ Superior Strength & Safety

Tempered for 4–5× strength compared with annealed glass

Safe breakage pattern reduces injury risk

Compliant with EN 12150, ANSI Z97.1, SGCC, AS/NZS 2208

✔ Excellent Optical Clarity

Perfect for applications requiring high color accuracy

Ideal for museum displays, storefronts, aquariums, and high-end furniture

✔ Stable Quality Control – MIGO GLASS

Automated furnace temperature monitoring

Optical distortion control < 0.2 mm/m

Edge polishing and safety arris available

Optional heat-soak test according to EN 14179

✔ Custom Manufacturing

Sizes up to 3300 × 6000 mm

Thickness from 4mm–19mm

Custom cutting, edge finishing, drilling, and screen printing

Ultra-clear / Low-Iron Tempered Glass Specifications

| Parameter | Ultra-clear / Low-iron Tempered Glass |

|---|---|

| Iron Content (Fe₂O₃) | ≤ 0.015% |

| Visible Light Transmittance | 91–92% |

| Color Appearance | Crystal-clear, minimal green tint |

| Thickness Options | 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm |

| Max Size | 3300 × 6000 mm |

| Strength | 4–5× stronger than annealed glass |

| Safety Standard Compliance | EN 12150, ANSI Z97.1, SGCC, AS/NZS 2208 |

| Heat Soak Test (optional) | EN 14179 |

| Fragmentation | Complies with global tempered safety glass requirements |

| Edge Finishing | Flat-polish, beveled, C-edge, safety arris |

| Custom Processing | Holes, cutouts, CNC, silk printing |

Tempered Glass Processing Step

FAQ

Q1: How to judge the quality of float glass?

Flatness, transparency, colorless, impurities, bubbles, etc.

Q2: How to reduce the self-implosion?

The high-quality float method is used for hot-dip treatment, edge treatment, and proper

stress intensity. Pay attention to avoid side collision of glass during installation.

Q3: Scope of use of tempered glass?

Safety is not involved in some parts of the building, but it is necessary to install toughened

glass to improve the compressive strength and explosion-proof capacity, and not to endanger

the safety of the person.

Q4: When tempered glass is broken, is the grain smaller the better?

No, the smaller the particle, the easier it is to explode.

Q5: Can tempered glass and heat-strengthened glass be made into laminated glass?

Can't. The national standard stipulates: the glass that stresses the difference cannot make laminated glass, because in the use process, the pressure that two pieces of glass bear is different.

Welcome your inquiry, we will reply within 12 hours

Hot Tags: low iron tempered glass suppliers China, manufacturers, factory, wholesale, customized, cheap, buy discount, in stock, price, made in China, 10mm Tempered Bathroom Wall Corner Glass Shelf, Clear Tinted Tempered Glass, Factory Offer 3mm to 19mm Tempered Glass, Low Iron Tempered Glass, Tempered Glass for Lighting, Transparent Casement Window Glass

![[[smallImgAlt]]](/uploads/10535/super-clear-low-iron-tempered-glassead1b.jpg)