Glass is a versatile material that is widely used across various industries, including construction, interior design, automotive, and electronics. Its appeal lies not only in its transparency and aesthetic qualities but also in its ability to be customized to fit specific needs. One crucial aspect of glass customization is the edge treatment, which enhances the appearance and improves safety and functionality.

There are several types of glass edge finishes available, each serving its own purpose. These finishes not only enhance the visual appeal of the glass but also contribute to safety and functionality. For instance, a flat polished edge provides a clean and professional look, while a beveled edge adds a decorative touch. A seamed edge is commonly used for hidden or framed glass, ensuring a safe and smooth finish without the need for additional polishing.

Glass edge finishes are integral to the customization process, enhancing the appearance, safety, and functionality of the glass. Understanding the available options and considering your specific requirements will help you make an informed decision when selecting the ideal edge finish for your glass project.

Classified according to the fineness of the edge, glass edge processing can be divided into cutting edge, seamed edge, rough grinding edge, fine grinding edge, and shiny polished edge.

1.Cutting edge technology is utilized during the production of raw glass sheets directly from the production lines at raw glass factories. The glass sheets are manufactured in Jumbo sizes such as 4800×3660mm, 3660×2440mm, and others. These glass sheets are later processed and cut into different sizes and shapes at glass processing factories.

The seamed edge, which is also known as a chamfered edge, is a basic glass edgework created by lightly sanding the sharp edges of the glass with a sanding belt. This type of edging does not result in a smooth, aesthetically finished edge and is not intended for decorative purposes. Despite lacking decorative appeal, a seamed edge effectively minimizes the risk of injury from handling or accidental contact with the glass.

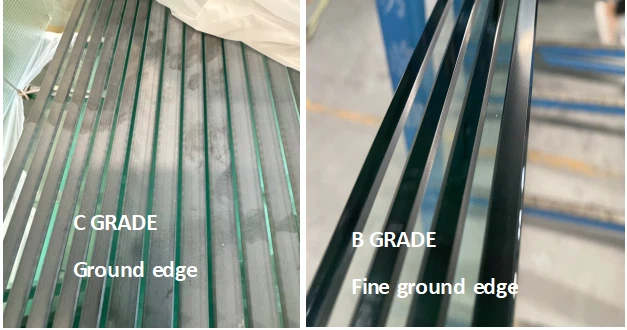

A grounding edge pertains to a glass edge that has been smoothed and refined by grinding away the sharpness. This method includes using a grinding wheel or belt to eliminate any rough or jagged edges, resulting in a smooth and polished surface. Ground glass edges come in two variations: rough ground edges and fine ground edges.

3.1 A ground glass edge (MIGO C grade) with a rough finish refers to the process of grinding down the edges of glass to remove sharpness without further polishing for a smooth appearance. Coarse abrasives or grinding tools are used to achieve this slightly textured finish.

3.2 On the other hand, a fine ground glass edge(MIGO B grade) is a polished and smooth edge resulting from grinding down the rough edges of glass. This method produces a precise and safe-to-handle edge, commonly found in glassware, mirrors, and other glass products to give them a professional finish.

4.A shiny polished glass edge refers to a smooth and glossy finish that has been achieved by polishing the edge of a piece of glass. This process involves using abrasive materials and techniques to remove any imperfections and create a sleek and reflective surface. Shiny polished glass edges are often used in high-end glass products, such as decorative items, furniture, and architectural features, to enhance the overall appearance and quality of the glass.

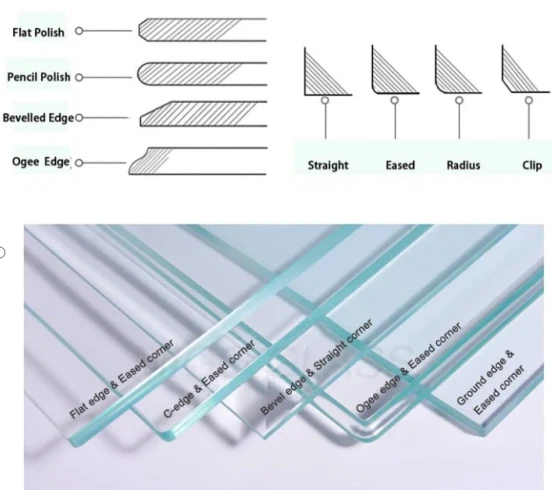

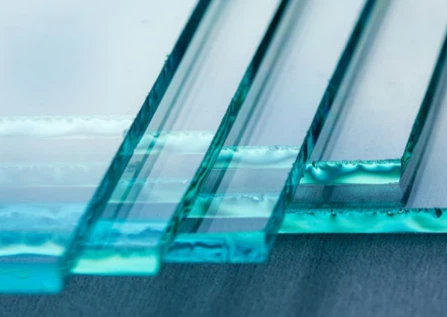

Classified according to edge appearance, common glass edges include flat edge, pencil edge/C-edge/round edge, beveled edge, ogee edge, etc.

- Flat glass edge refers to the smooth, flat surface of a piece of glass that has been cut and finished to have straight, even edges. Flat glass edges can be achieved through various cutting and finishing processes, such as grinding, polishing, and beveling.

- A pencil glass edge, also known as C-edge and round edge, is a type of edge finish for glass that is characterized by a rounded, smooth edge that resembles the shape of a pencil. The rounded edge helps to prevent chipping and provides a more sleek finished look to the glass. Pencil glass edges can be achieved through grinding and polishing processes that shape the edges of the glass into a gentle curve.

- A beveled glass edge is a type of edge finish for glass that is characterized by a slanted or angled edge that creates a decorative and elegant look. Beveled edges are achieved by grinding and polishing the glass at a specific angle, typically around 45 degrees, to create a chamfered edge that reflects light and adds dimension to the glass.

- An ogee glass edge is a type of edge finish for glass that features a distinctive S-shaped curve. This edge profile is created by grinding and polishing the glass in a way that creates a concave arc followed by a convex arc, resulting in a graceful and decorative edge.

When selecting the type of glass edge, various factors should be taken into account, including aesthetic preferences, functionality, safety requirements, and budget limitations. Whether you prioritize a modern and polished look or focus on safety and longevity, there are glass edge treatments available to meet your needs. Understanding the characteristics and uses of different edge types enables informed decision-making when choosing glass for your project, ensuring a harmonious blend of style and practicality.

Different glass edge finishes cater to specific purposes, and it's essential to consider the intended use and design criteria. Proper handling and installation of the glass with the suitable edge type are vital for its long-term structural performance and safety. By choosing the appropriate edge finish and following the correct installation procedures, you can maximize the functionality, visual appeal, and overall safety of the glass system. Thoughtful consideration and knowledgeable choices will lead to the desired outcomes in terms of both appearance and functionality for your project.