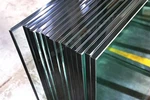

Low Iron Solar glass also called photovoltaic glass which mainly used on solar panels because of its super light transmittance rate. The solar panel is a thin layer of optoelectronic semiconductor that converts solar energy into electricity. By considering its efficiency, we are using High transmittance and low reflection glass for its panel. This high-strength glass maintains the best image quality by eliminating unwanted distortions with advanced optical technology.

The solar panel glass can choose Low iron float glass, Low iron patterned glass, AR low iron float glass, and AR low iron patterned glass. 3.2mm and 4mm thickness low-iron solar glass is widely used for solar panels and solar collectors.

Product Specification

| Glass type | Low iron glass |

| Thickness | 3.2mm, 4mm |

| Max size | 1200mm*2200mm or Customized |

| Min size | 200*200mm or customized |

| Light transmittance | >91.3% |

| Thickness tolerance | ±0.2mm |

| Dimension tolerance | ±1.0mm |

| Diagonal difference | ≤0.1-0.2% |

| Overall bow/warp | <0.2% |

| Fragmentation test | ≥40 particles within 50x50mm |

Migo Solar Glass Series

1) 3.2mm / 4mm Clear Float Solar Glass

2) 3.2mm / 4mm Ultra Clear Float Solar Glass (with ARC or Non-ARC )

3) 3.2mm / 4mm Clear Normal-Iron Patterned Solar Glass

4) 3.2mm / 4mm Low Iron Patterned Solar Glass (with ARC or Non-ARC )

Solar Glass Manufacturing Process

Solar Glass Packaging

1. Prior to packaging, the solar glass panels are thoroughly cleaned and inspected for any defects or damage. This ensures that only high-quality panels are packaged for shipment.

2. The solar glass panels are stacked and layered in a pallet or crate. The stacking process ensures stability and minimizes the risk of damage during transportation.

3. The interlayers or separators are used between the solar glass panels to provide additional cushioning and protection. The interlayers can be moisture-proof papers, powder, or other materials.

4. Put the solar glass panels into the plywood crates, and use straps and nails for packaging and fastening.

5. Each package is labeled with relevant information such as product details, quantity, handling instructions, and shipping labels.

The packaging process aims to safeguard the solar glass panels during transit, minimizing the risk of damage and ensuring that they arrive at their destination in optimal condition

FAQ:

1. How does your factory control quality?

Quality is a priority. We are a GMP and ISO 9000 factory. We pay high attention to quality control from the very beginning to the end during the whole glass process:

A: All raw materials we used are environmental-friendly;

B: Skilled workers care about every detail in handling the producing and packing process;

C: The quality control department is specially responsible for quality checking in each process.

2. Can we get samples of the low-iron solar glass for quality testing?

Yes, some products can be sent as free samples, but upon your payment of the shipping cost.

3. What is your normal lead time?

For stock products, can be immediately shipment after we receive your payment;

For OEM products, the lead time is 3-4 weeks after we receive your payment.

Hot Tags: Solar Glass suppliers China, manufacturers, factory, wholesale, customized, cheap, buy discount, in stock, price, made in China, High Solar Reflectivity Solar Mirror For Csp Suspension Heliostat, Solar Energy Glass, Solar Glass, Solar PV Glass, Tower Linear Fresnel Flat Solar Mirror For CSP Heliostat

![[[smallImgAlt]]](/uploads/202310535/3-2mm-4mm-low-iron-solar-glassd34d8d75-6afe-4576-b9d3-08c3fa5b04ac.jpg)