Product Overview

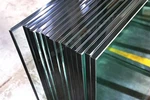

Product Name: Tempered Glass (Safety Toughened Glass)

Brand: MIGO Glass

Thickness: 3mm–19mm

Size: Standard size / Jumbo size / Custom cutting

Glass Types: Clear tempered glass, low iron tempered glass, tinted tempered glass, frosted tempered glass

Edge Finishes: Flat polished edge, arris edge, beveled edge

Strength: 4–5 times stronger than normal annealed glass

Certificates: CE, CCC, SGS, ISO 9001, ISO 14001

MOQ: 500 SQM

Payment: T/T, L/C

Port: Qingdao, China

Description

MIGO Tempered Glass is produced by heating high-quality float glass to over 650°C and then rapidly cooling it to increase strength and thermal stability. It is 4–5 times stronger than regular glass and breaks into small, blunt fragments for maximum safety.

As a leading architectural glass manufacturer, MIGO Glass supplies tempered glass for commercial buildings, residential projects, curtain walls, doors, shower rooms, railings, partitions, furniture, and transportation applications. Our products strictly comply with EN12150, ANSI Z97.1, AS/NZS 2208, meeting the requirements of North America, South America, and Europe.

We offer complete deep-processing services including cutting, CNC shaping, edge polishing, drilling, screen printing, lamination, and more.

Product Description:

When it comes to mirrors, there are many types and uses. Common types include aluminum mirrors, silver mirrors, safety mirrors, etc. Here, we will introduce to you the advantages and disadvantages of different types in terms of the definitions, characteristics and applications of these products, as well as how to choose a suitable mirror type.

Mirror Types

-

Aluminum mirror

This is a type of mirror where the reflective layer is made from aluminum rather than the more traditional silver. This aluminum layer is deposited onto the back of a glass substrate, typically through a process called vacuum deposition, where aluminum is vaporized and then condenses onto the glass, forming a thin, reflective coating.

-

Silver Mirror

This is a type of mirror that has a reflective surface made by depositing a thin layer of silver onto a glass substrate. The silver coating gives the mirror its high reflectivity and is often used in high-quality mirrors for decorative and optical purposes.

-

Safety Mirror

Safety mirrors are often made with a vinyl backing that helps hold the glass together if it breaks, reducing the chance of sharp shards flying off. There are two kinds of films for coated safety mirrors in MIGO GLASS, one is a smooth film backing CAT I, and the other is a non-smooth film backing CAT II.

-

Tempered Safety Mirror

This is a type of safety mirror that is made from tempered glass. Tempered glass is treated through a heating and cooling process to make it much stronger than regular glass. If it does break, it shatters into small, blunt pieces rather than sharp shards, which reduces the risk of injury. This type of mirror is often used in environments where safety is a concern, such as in public spaces or in homes with young children.

Differences Between Normal Mirror and Tempered Safety Mirror

-

Manufacturing Process

Normal Mirror: A normal mirror is made by applying a reflective coating, usually silver or aluminum, to the back of a sheet of regular glass. This glass is not treated or altered significantly after the reflective coating is applied.

Tempered Safety Mirror: A tempered safety mirror starts as a normal mirror but undergoes an additional tempering process. This involves heating the glass to a high temperature and then rapidly cooling it, which changes the internal structure of the glass, making it much stronger.

-

Strength

Normal Mirror: Normal mirrors are relatively fragile and can break or crack under impact. The glass used is not strengthened, so it is more susceptible to damage.

Tempered Safety Mirror: The tempering process makes these mirrors several times stronger than normal mirrors. They are more resistant to impact and thermal stress, making them more durable and safer for use in various environments.

-

Features

Normal Mirror: When a normal mirror breaks, it shatters into large, sharp shards of glass, which can be very dangerous and cause serious injuries.

Tempered Safety Mirror: If a tempered safety mirror breaks, it shatters into small, blunt, pebble-like pieces that are much less likely to cause injury. This makes them safer, especially in environments where glass breakage could pose a significant hazard, such as in bathrooms, gyms, or public spaces.

-

Applications

Normal mirrors are commonly used in residential settings where the risk of impact is low, such as in bedrooms, and living rooms.

Tempered safety mirrors are used in locations where safety is a priority, including bathrooms, gyms, and public buildings. They are also often required by building codes in commercial and public settings due to their safety features.

-

Cost

Generally, normal mirrors are less expensive than tempered safety mirrors due to the simpler manufacturing process. But the increased safety and durability often justify the higher cost in many applications.

Mirror Glass Packing and Loading at MIGO GLASS

Mirror sheets packing and loading require careful handling to prevent damage during transportation.

-

Inspection

Before packaging, the mirrors are inspected for any defects, scratches, or chips to ensure only high-quality sheets are packed.

-

Protective treatment

A protective film or paper (such as polyethylene or kraft paper) is often placed between each mirror sheet to prevent scratches

during handling and transport. For edge and corner protection, foam strips, plastic corner protectors, or cardboard strips are

often placed along the edges of the mirrors to protect against chipping.

-

Stacking

Mirror sheets are stacked vertically or horizontally, depending on their size and the type of packaging used. For larger mirrors,

vertical stacking is common as it reduces the risk of breakage from weight pressure.

-

Strapping

The stack of mirror sheets is securely strapped together, often using plastic or metal bands, to keep them from shifting during transit.

-

Packaging Options

Wooden Crates: Mirror sheets are commonly packed in custom-made wooden crates. These crates are typically lined with foam or

other cushioning material to absorb shocks.

Foam Lining: Foam or other cushioning material may be used inside the crates to provide extra protection against vibrations and impacts.

Shrink Wrapping: In some cases, the entire package is shrink-wrapped to provide an additional layer of protection against moisture

and dirt.

-

Loading

Forklifts, cranes, or vacuum lifters are used to load the packed mirror sheets onto the containers. The equipment is chosen based on the

size and weight of the mirrors. Besides, inside the container, the crates are secured using straps or tie-downs to prevent movement during transit. Additional padding

may be used to fill any gaps and prevent the packages from shifting.

|

|

At MIGOGLASS, we offer many types of mirrors, silver mirrors, aluminum mirrors, copper-free and lead-free mirrors, safety mirrors, laminated mirrors, tempered mirrors, etc. It is widely used in bathrooms, gyms, dance studios and other interior decoration places, as well as various types of home furnishings and furniture.

FAQ

Q1. What is tempered glass?

Tempered glass is safety glass that has been heat-treated to increase strength and improve safety. It breaks into small, blunt particles when shattered.

Q2. How strong is tempered glass?

It is 4–5 times stronger than regular annealed glass.

Q3. Can tempered glass be cut after tempering?

No. Cutting, drilling, or edging must be completed before tempering.

Q4. What sizes can you produce?

We can produce up to 3300 × 7000 mm, and small customized cut sizes are also available.

Q5. Can you provide tempered laminated glass or insulated glass?

Yes. MIGO offers tempered laminated, tempered insulated (IGU), and tempered printed glass.

Q6. What is your production lead time?

Normally 15–30 days, depending on processing requirements.

Q7. Do you offer samples?

Yes, small glass samples are free; customers only need to pay for express freight.

Hot Tags: Tempered Safety Mirror suppliers China, manufacturers, factory, wholesale, customized, cheap, buy discount, in stock, price, made in China, Colored Mirror Safety Glass Sheet, Customizable Silver Mirror Glass, Large Mirror Sheets, Large Silver Mirror, Migo Decorative Colorful Mirror, Silver Mirror Glass Manufacturer